Coal mine elevator is an important equipment in the production process of coal mine, iron mine and nonferrous metal mine. The safe and reliable operation of the elevator is directly related to the production status and economic benefit of the enterprise. Coal is mined underground, and the coal is pulled to the surface by a tilting shaft with a hoist. The coal car is similar to the freight car of a train, but smaller in height and volume. There is a winch hoist at the wellhead, driven by the motor through the reducer to drive the drum to rotate, the wire rope is wound on the drum for several weeks to hang a train of coal cars, driven by the motor to drag the train full of coal up or down the inclined shaft. This kind of drag system requires the motor to start forward and reverse frequently, slow down and brake, and the motor speed changes according to certain rules. At present, most of the small and medium mines adopt the inclined shaft winch hoisting, the traditional inclined shaft hoist generally adopts the ac winding motor series resistance speed regulation system, the resistance switching relay - ac contactor control.

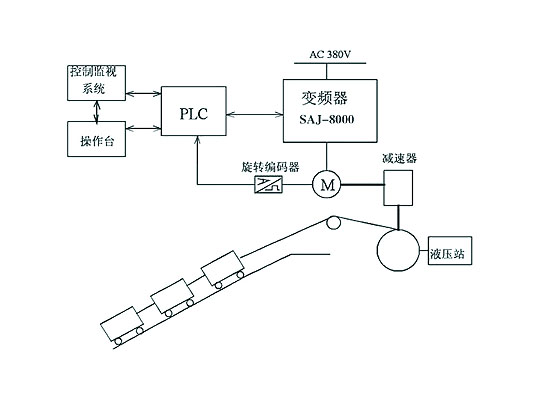

In order to overcome the shortcomings of the traditional ac winding motor series resistance speed regulation system, the inverter speed regulation technology is used to transform the elevator, which can realize the constant torque control in the full frequency (0 ~ 50Hz) range. For the treatment of regenerative energy, the low cost energy consumption braking scheme or the more significant energy saving regenerative braking scheme can be used. For safety, hydraulic mechanical braking needs to be retained, and the hydraulic mechanical braking and the transducer braking are integrated in the design process. The frequency conversion speed regulation scheme of mine hoist is shown in figure

Considering that the torque of the wound motor is greater than that of the squirrel cage motor and the overload capacity is stronger, the original 4-pole 55kW wound motor is still used. When driven by a frequency converter, the three leads of the rotor need to be short-connected. During the operation of the hoist, downhole and wellhead must be connected by signals. If the signals are not confirmed, the hoist cannot operate. In order to display the position of the carriage during operation, the e6c3-cs5c 40P rotary encoder is used, that is, the motor rotates one turn to generate 40 pulses, so that the distance traveled by the carriage corresponding to each two pulses is 1200× /(24×40)=3.927, which is about 3.9mm. The error value between the distance and the actual distance is 4-3.9=0.027mm, the error value between the drum and the actual distance is 0.027×40×24=25.29mm, and the length of the wire rope is 120m. If the distance traveled by the corresponding carriage of the two pulses is calculated with an approximate value of 3.9mm, the error value of the whole distance of 120m is 25.92× 120,000/1200 ≈825mm.

Considering that there is a pulse error in the actual detection process, the error is between 821mm and 829mm, and the error range is less than 1m for tens of meters of carriages, with sufficient precision. Therefore, a counter is used to count the number of pulses emitted by the rotary encoder in real time, then the position of the carriage can be calculated and displayed on the monitor. Another question is is there any cumulative error in the counting process? In the actual test, the counter is reset before a lifting process begins. When the first heavy car passes a certain position, the counter is opened to count. The position of the car in the inclined shaft is calculated based on this point, with no cumulative error. On the operating table, an 8-inch touch screen displays ac voltage and motor working current as well as the position of the carriage.

The load characteristic of the hoist is the constant torque potential energy load, and the starting torque is large. When selecting the inverter, there is a proper margin. Therefore, the inverter transformed by the coal mine elevator adopts ambiton AMB600132kW inverter. Because the hoisting machine is in the electric state most of the time, only in a few times there is the generation of renewable energy.

The inverter is connected with a braking unit and a braking resistor, which can meet the regenerative braking of the downlink of the heavy vehicle and realize the smooth downlink. The wellhead also has a hydraulic mechanical brake, similar to the electromagnetic lock brake, which is used for braking when the heavy truck is stationary, especially when the heavy truck is parked on the slope of the inclined shaft. Hydraulic mechanical brake controlled by PLC and frequency converter, whether mechanical brake braking under the control of the inverter frequency reaches the port, starting when the inverter output frequency to set data, for example, 0.2 Hz, A and B port output signal frequency converter, motor torque is enough big, open the brake hydraulic machinery, heavy vehicles can be upward; During the deceleration process, when the frequency of the inverter drops to 0.2hz, it indicates that the motor torque is already small, and the hydraulic mechanical brake stops the motor. In case of emergency, press the emergency stop button. The energy consumption brake of the inverter and the hydraulic mechanical brake work together to make the elevator stop in as short a time as possible.

The traditional operation mode of the hoist is that the operator sits in front of the operating table at the head of a coal mine, holding a joystick to control the forward and reverse speed of the motor. In order to adapt to the operation mode of the operator, the frequency converter adopts stepless (stepless) speed regulation.

Because the frequency converter has soft start, smooth speed control over a large area, and the advantages of energy saving effect is remarkable, so comprehensive investigation, decided to adopt the shenzhen amb electric co., LTD. Production series inverter frequency conversion to hoist system modification, after several months of running, prove reconstruction effect is more ideal, mainly displays in:

1. Soft start and soft stop at startup are realized to reduce the impact on the power grid.

2. The frequency of frequency converter is continuously adjusted to make the speed adjustment more convenient, reliable and stable.

3. After using the inverter, the original shifter contactor and speed-regulating resistance were eliminated, which saved the maintenance cost and reduced the downtime and maintenance time, thus increasing the output. At the same time, the harsh operating environment is improved, so that workers can avoid working under the high temperature condition when the speed regulating resistance becomes hot in summer.

4. It is very effective at low speed. At a depth of more than 300 meters, the mine is measured using a 4/50 watt-hour meter. With the same power consumption, the working frequency can be pulled by 17 hooks, while the frequency conversion can be pulled by 26 hooks, that is, the frequency conversion can be pulled by 9 hooks more than the working frequency. It is estimated that the electricity saving rate is about 20%. Because of the use of frequency converter, the equipment is basically full load operation. Even if we adopt the conservative algorithm and discount the 132KW motor power to 120KW, only use it for 20 hours a day and work 360 days a year, the annual power saving is still as high as 302,400 KWH (120*0.35*20*360=302400 KWH). If calculated at 0.5 yuan per kilowatt-hour (local electricity price 0.6 yuan), the annual electricity bill can be saved by more than 150,000 yuan (302,400 *0.5= 151,200 yuan).

Winding type motor rotor resistance speed regulation, resistance consumption of a large number of differential power, the lower the speed, the greater the consumption of differential power. Use frequency conversion speed regulation, is a kind of energy - free efficient speed regulation. The elevator is in the electric state for most of the time, and the energy saving is very significant. In addition, the frequency conversion speed adjustment of the hoist can greatly improve the stability and safety of the system operation, reduce operation faults and shutdown hours, save manpower and material resources, improve the coal transport capacity, indirect economic benefits are also considerable.

|

|

|

| The public, | Mobile station |

0755-81719517

0755-81719517

|

|

0755-81719530 0755-81719530 |

amb@ambition.com.cn amb@ambition.com.cn |

Floor 1, 5 and 6, building 7, lijincheng science and technology industrial park, gongye dong road, longhua new district, shenzhen Floor 1, 5 and 6, building 7, lijincheng science and technology industrial park, gongye dong road, longhua new district, shenzhen |

|