[industry introduction]

Slitting machine is a wide paper, mica tape or film slitting into a number of narrow materials of mechanical equipment, often used in papermaking machinery, wire and cable mica tape and printing and packaging machinery. Slitting machine is mainly used in: mica tape, paper, insulating material and film slitting, especially suitable for narrow tape (insulating material, mica tape, film, etc.) slitting.

As the degree of mechanization is higher and higher, the requirements for the efficiency of the winding operation are also higher and higher. When the slitting machine is used in the film, tape and paper slitting operation, it can be divided into a number of small rolls according to different requirements, to meet the needs of different occasions. Of course, the slitting machine can also be used in other production areas where winding work is required.

There are many kinds of slitting machines on the market, but there are many defects and deficiencies at the same time, for example: traditional slitting machines use input paper thickness calculation, so the actual diameter error is large, but also need to monitor the real-time tension control accuracy, when the tension is too loose and tight, the need to manually change the parameters. Adopting the control system of slitting machine can solve these problems well, and the thickness of coil diameter can be calculated in real time. Simple parameter setting, when the normal operation of the machine can be separated from manual operation, independent operation of the machine, more intelligent and humanized.

[working principle]

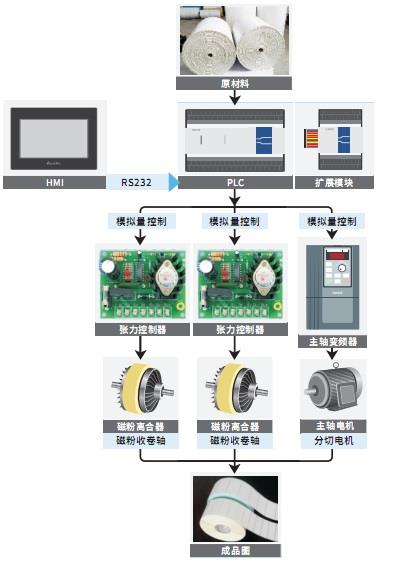

All-magnetic powder platform slitting machine

Full magnetic powder single winding slitting machine

Full magnetic powder double winding slitting machine

A large motor is used to drive the rewinding shaft, and a magnetic powder clutch is added to the rewinding reel. By adjusting the current of the magnetic powder clutch, the resistance generated by it is controlled to control the tension of the material surface. Magnetic powder clutch and brake is a special automatic implementation element, it is through the magnetic powder filled in the working gap to transfer torque, change the magnetic current can change the magnetic state of the magnetic powder, and then adjust the transferred torque. It can be used for stepless speed regulation from zero to synchronous speed. It is suitable for fine adjustment of high speed segment and speed regulation system of medium and small power. It is also used in uncoiling or rewinding tension control systems where the torque is adjusted by current regulation to ensure that tension remains constant during winding.

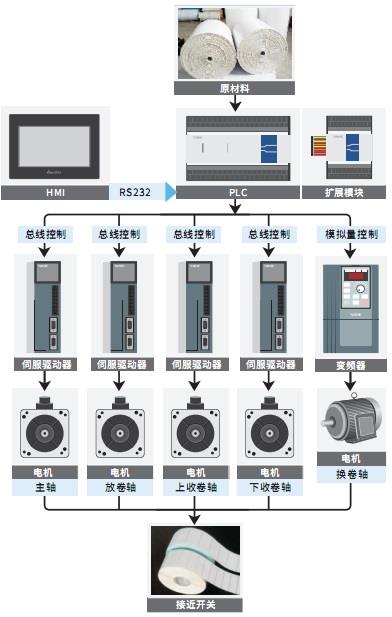

4 servo slitting machine

3 servo slitting machine

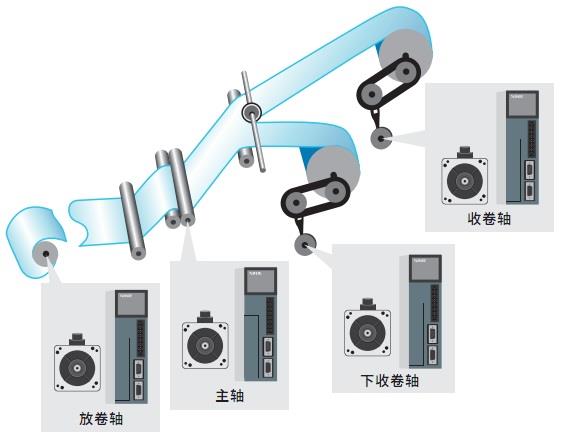

Start the main drive motor, drive fixed at the edge of the automatic controlling mechanism is put on the volume of gas rose axis transmission, through the transition roller, roller is equipped with photoelectric tracing head above the transition, realized in the on-line detection in the process of production, the function of collecting data, ensure the equipment operation, high accuracy and high productivity transition roller drive the tension detection roller, drive roller operation, working gas knife pad steel roller, at the same time in the air knife steel roll at the top of the cutting knife cylinder driven by the pressure to cutting material.

[system topology]

All magnetic powder platform

Four-servo slitting machine

【 process principle 】

[field application]

[system features]

◆ the program applies the specific algorithm to calculate the winding diameter in real time, and the control of tension and speed is more stable;

◆ full servo slitting machine system adopts bus speed mode, the control response is faster, the tension control is ± 0.5n;

◆ full magnetic powder separator system, speed up to 240 m/min; Full servo slitting machine system, speed up to 360 m/min;

The program adds the starting compensation, tension taper compensation, coil size compensation and other compensation effects, so that the winding effect is better.

|

|

|

| The public, | Mobile station |

0755-81719517

0755-81719517

|

|

0755-81719530 0755-81719530 |

amb@ambition.com.cn amb@ambition.com.cn |

Floor 1, 5 and 6, building 7, lijincheng science and technology industrial park, gongye dong road, longhua new district, shenzhen Floor 1, 5 and 6, building 7, lijincheng science and technology industrial park, gongye dong road, longhua new district, shenzhen |

|